Life can take many turns. What today needs to be a group workspace in an office may tomorrow be better suited as separate units for individual tasks. These requirements for increasingly flexible equipment are leading to a change in the production sector: the shift from manufacturing furniture pieces to designing true systems for almost infinite uses. We tell you about it through three recent paradigmatic examples.

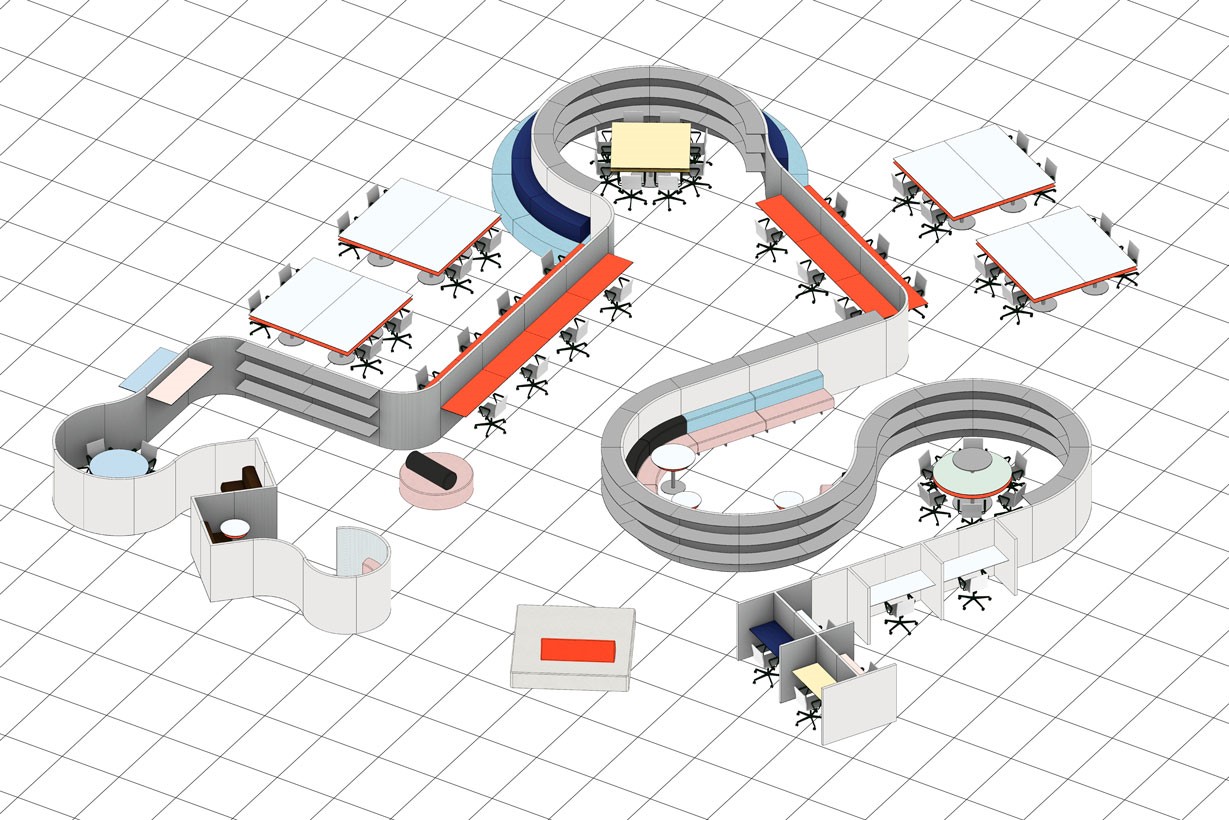

100 modules for a million options

OMA has created Principles for UniFor, a collection of a hundred modular elements that give people the freedom to configure their own workspace. It transcends the idea of just having a table, storage, or independent partitions that relate to each other. It is a true constructive strategy that makes it possible to extend the useful life of the equipment while integrating into any change.

Reconfigurable scaffolding

Vitra created Comma as a plug&play-like method: a scaffolding structure that can be reassembled over and over again in different variations with the aim of designing the ideal work environment according to needs. It allows for a greater number of shelves, deploying a larger table for a specific moment, or facing positions.

Ver esta publicación en Instagram

The kitchen multiplied anywhere

The kitchen is another territory where uses and customs were modified. Unfortunately, it was the type of space that had more difficulty adapting to the new model, focused on a vision as a social meeting and interaction point. We say “was” because the Big Bang Kitchen project created by Cierto Estudio and presented at World Design Capital Valencia 2022 showed that this rigid configuration could “explode” (hence its name) into modules that facilitated an outdoor cooking place, tables and chairs for an intimate dinner or snack with the gang… In short, having a different kitchen depending on the occasion.