Noemí Cortizas, a Spanish designer who lives in France, found her place when she combined her mechanical engineering side with her passion for designing for people, a combination that led her to CMF (Colour, Materials, Finish).

What’s special about CMF? Cortizas says that it allows her to experiment with colours, materials, and finishes through her Paris-based company Ydemaker as well as her new Spain-based project Material Innovation Hub.

This product designer is determined to show that there is still room for innovation, and she is doing just that through her own work as well as by educating others in collaboration with the Axencia Galega de Innovación (Galician Agency for Innovation). Let’s connect with her and found out more about what she does.

CMF: Colour, Materials, Finish

What is CMF?

It’s something that has been happening in the automotive industry for a while, where CMF designers are known as Colour and Trim designers. They work on the car’s interior, because that’s where we spend the most time and it needs to be comfortable, but they also work on communicating a brand.

It’s a hybrid specialisation because there’s no specific training for it. I’ve come across people working in CMF that started in textiles, industry, materials technology, mechanical engineering…because it’s not just about understanding what’s on the horizon in the consumer market, it’s also about having the scientific background to know how materials work and to make ideas a reality. It’s a field that combines the emotional and visceral with science.

So, CMF combines design, science, and technology.

Exactly. For example, a really important part of CMF is colour. But the colour, depending on the type of material, the process, and the application, can be affected by a varnish, the internal pigmentation of a material, a combination of pigments…what’s known as the physical behaviour of a material.

Achieving the colour blue, which might seem quite simple, requires a scientific study about the material that the colour will be applied to and the method of application so that it’s compatible with its intended use. Some colours are very difficult to achieve.

Is that the aspect of research that you like the most?

I like both sides. I like the mechanical engineering side, the more scientific, molecular part, that’s more about innovation and how things work. On the other hand, I like CMF and design, because you’re designing for people. The result you achieve isn’t something that stays hidden, but rather it will provoke a reaction when somebody holds your product in their hands. You have studied something carefully, starting with the initial idea, then gone through the development of a research process, and you’re going to get a reaction. That reaction will vary greatly. You generate emotions, emotional links, and that’s very interesting.

Creating a sensory experience for a brand

Did you start your company Ydemaker because of that interest in research?

When I started out in this field at design school, I had already analysed the scientific aspect of materials. I had started out in the world of sensory experience, so I asked my professor what I could do in that field. He told me I could work on the literature, because there were no other options.

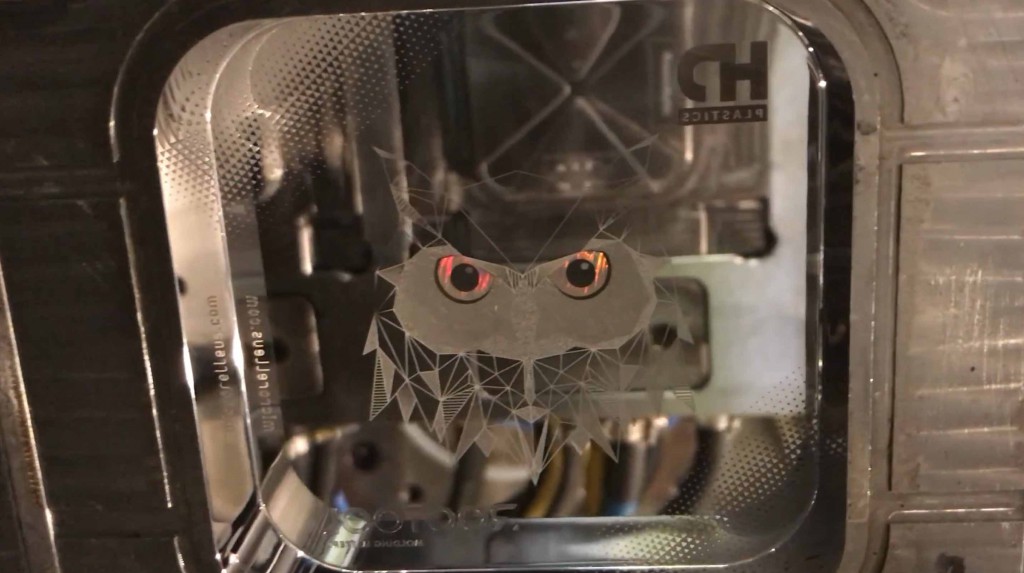

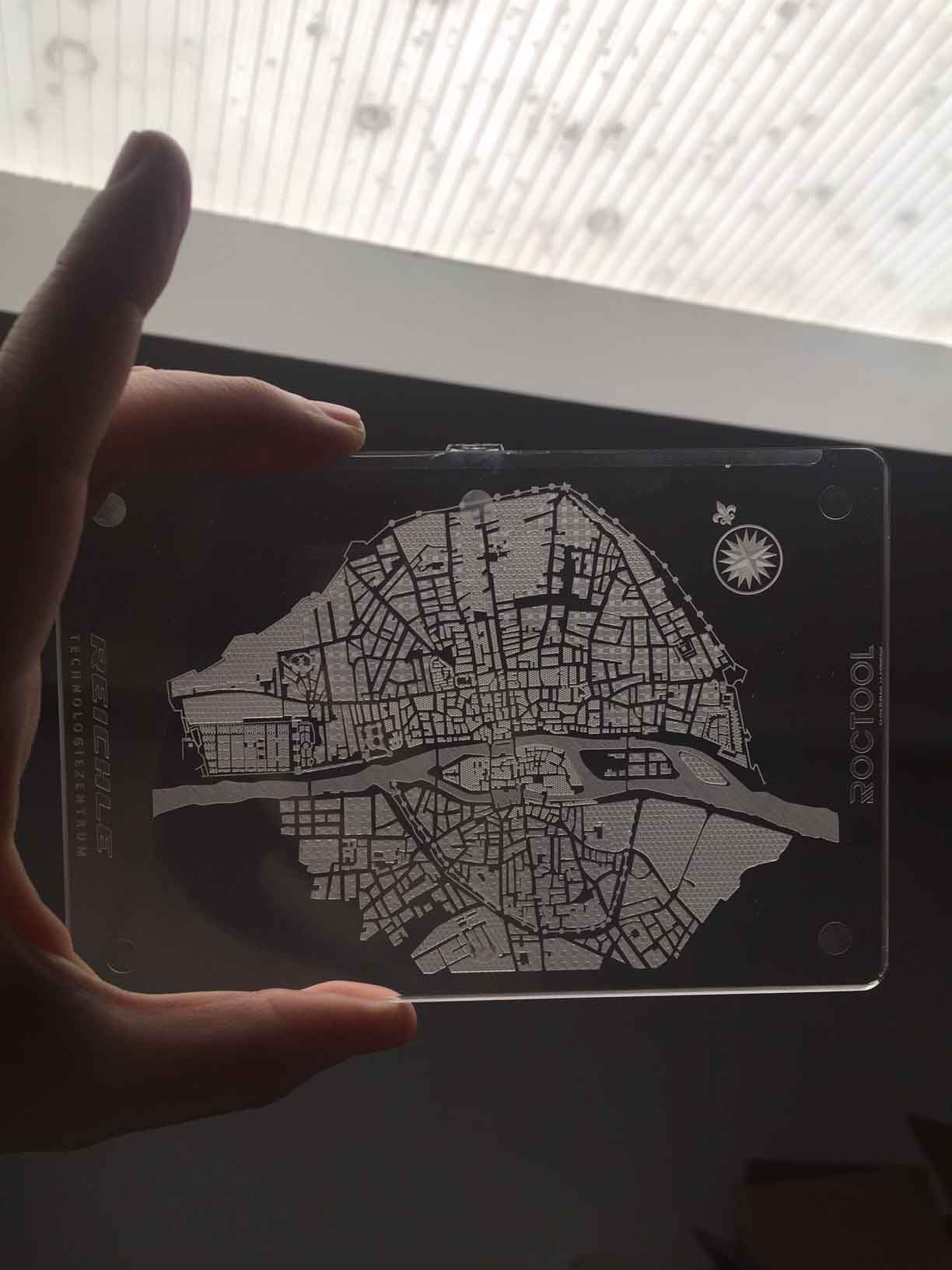

I always liked the sensory side of things and it was something I was able to work on during my time at Roctool. I worked on automobile interiors and luxury cosmetics. They are two very different worlds and each one is concerned with something different. My job was to make a brand’s vision a reality using Roctool technology. I had to understand their vision, give shape to it using CMF, and then look at how to achieve it using the technology. The design acted as my guide and I would try out different processes until I had a prototype.

I’ve always really liked innovation, design, and the scientific side of things, and when I discovered CMF, I fell in love. But then COVID-19 came along, and I had to reinvent myself, so I decided to create Ydemaker.

Roctool technology made it possible to explore high-end innovative finishes for packaging and products

Ydemaker was followed by Material Innovation Hub. How did that come about?

Spain is a bit behind in terms of materials, innovation, colours, and techniques. That’s why we created MIH with the people from Tattoo. We are always talking about how Galicia should be competitive, but that’s not the way it is. For example, I was surprised to learn that there were some very interesting things in the Galician materials library that weren’t being taken advantage of. There are materials and ideas out there that can be more widely used because there is a need for them in the market.

Many people believe that design is about making complex things or objects that belong in a museum, but that’s not the case. The design of materials and finishes can be very useful. One famous example is video game console controls, of which there are an infinite number of varieties. This is a study in CMF. They change the colours and the pigments, but the injection moulding process is the same. By simply changing the materials, you can make different versions of the same product that allow you to reach different markets and different consumer targets.

Connections with design

Is design synonymous with luxury?

No. For me, design offers solutions that are viable on an industrial scale to an existing market. Everyone designs. Everyone that is thinking about a viable solution is coming up with a design. Design is not inextricably linked to luxury; it doesn’t have to be expensive. It’s simply necessary.

How much influence does design, specifically CMF, have on a consumer’s perception of a product?

I’ll give you an example. I was talking to a group of people who were studying how quality is perceived in France, and they told me that their clients from the cosmetic world were working on new packaging, positioning it alongside the competition’s products. When a person walked in, they studied where this person stopped and the path that they would follow, and they calculated the person’s reaction time. If this person picked up the product, if it caught their attention, and if they spent more time with it than with other products, the packaging viewed as successful. This shows the importance of CMF, because we are talking about a reaction to visuals, an effect that occurs in a just a few seconds.

What you’re really doing is creating a connection, but how aware is the consumer that this is what is happening?

They aren’t aware at all. When it comes to touch, for example, if something has a pleasant feel or not…You pick up the product and, if it feels unpleasant, you put it down. This is very obvious in the cosmetics world. Each brand has a different language when it comes to shapes and finishes. Some products might have the same shape, but when you hold the product in your hand, there is something about the feel of it that stays with you.

What’s the process behind achieving that emotional connection?

There are two possible situations that I usually face: the client that knows exactly what they want and the client who isn’t sure about what they want, but they know they want to improve what they are currently doing. This is a where a study of market trends comes in, meaning identifying the directions that consumer trends are heading and translating this into a colour, a finish, a material, a shape. That’s the first stage.

Ver esta publicación en Instagram

I also have to know about the types of industrial technology that are going to help me execute these ideas. This requires a lot of research, knowing about industrial mechanics, manufacturing technology, if new things are being developed…One must always be learning. Then I have to analyse what type of material I’m going to use, what type of finish, and the colour. Once I have all of that, I do the first test.

It’s an iterative process. I identify what works, what doesn’t work, I talk to suppliers…It’s similar to art direction. You create your artistic idea and then you manage the different facets required to achieve the result you’re looking for.

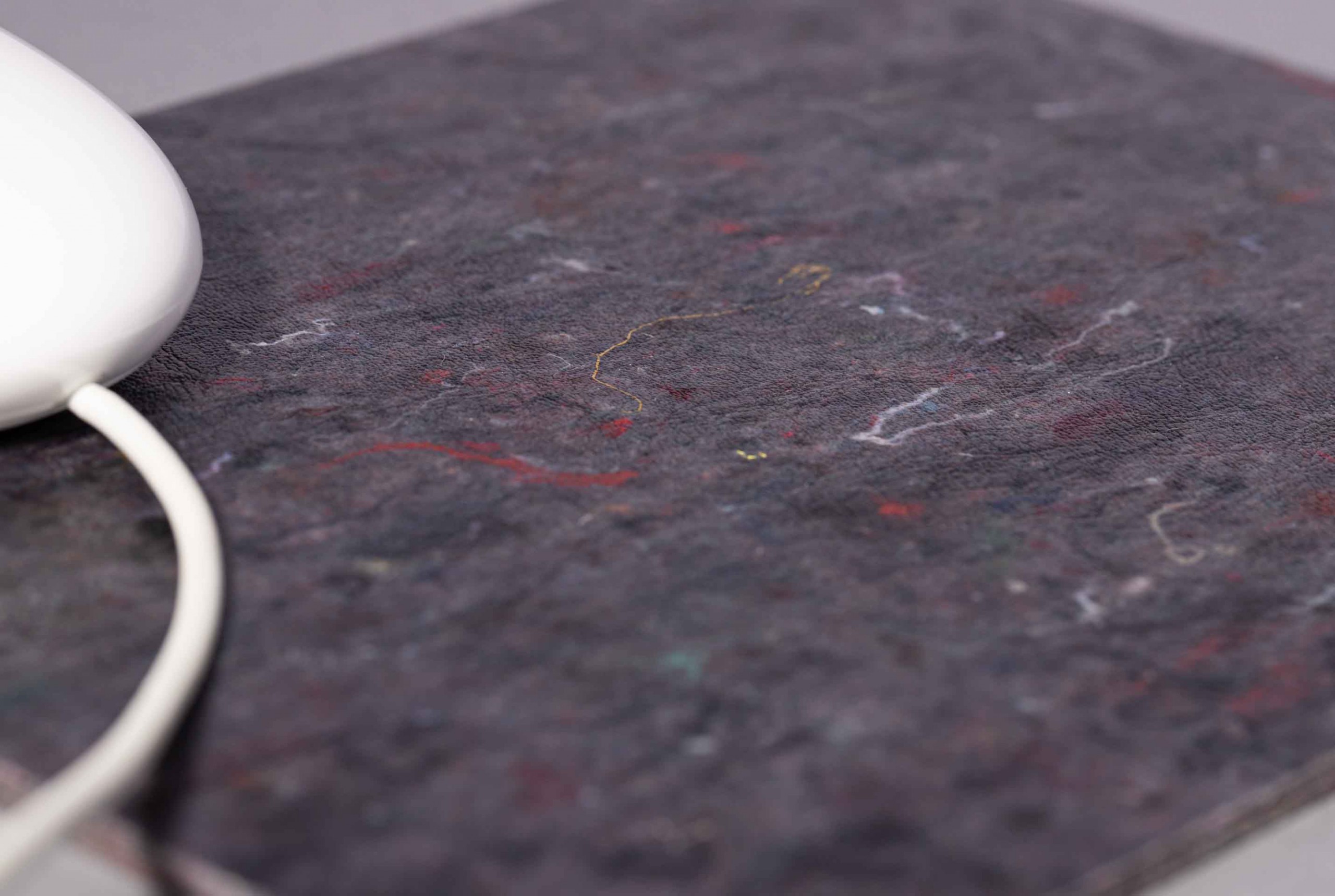

That’s what happened with the Auchan Retail project, which focused on materials made from recycled clothes. When we did some tests, we saw that some pieces came out burnt. Something wasn’t working. We looked at composition, we tried different temperatures…It’s all part of the testing process.

The same thing is happening with another material [I’m working on], a bioplastic made from coffee grounds that is very interesting, but that smells very strongly of coffee. We thought it was too strong a smell for the client, so we have to optimise it to see how we can change it.

Which part of the process do you most enjoy?

All of it. I can’t choose just one thing because I’m a very cross-disciplinary person. At the beginning, when I was working more on the engineering side and less on the design side, I felt a bit unfulfilled. I can’t choose one over the other because they are both very important. Let’s just say that the creative side and the scientific side of my brain are both satisfied.

Is the pandemic going to influence CMF?

Yes. People want to buy less, but they want to buy better quality. Above all, they want things to be more sustainable. It’s very important to try to create truly sustainable options that last. A fabric that only lasts a year just won’t cut it anymore. We have to look for alternatives and we have to try and communicate, because people are going become less trusting.

Materials

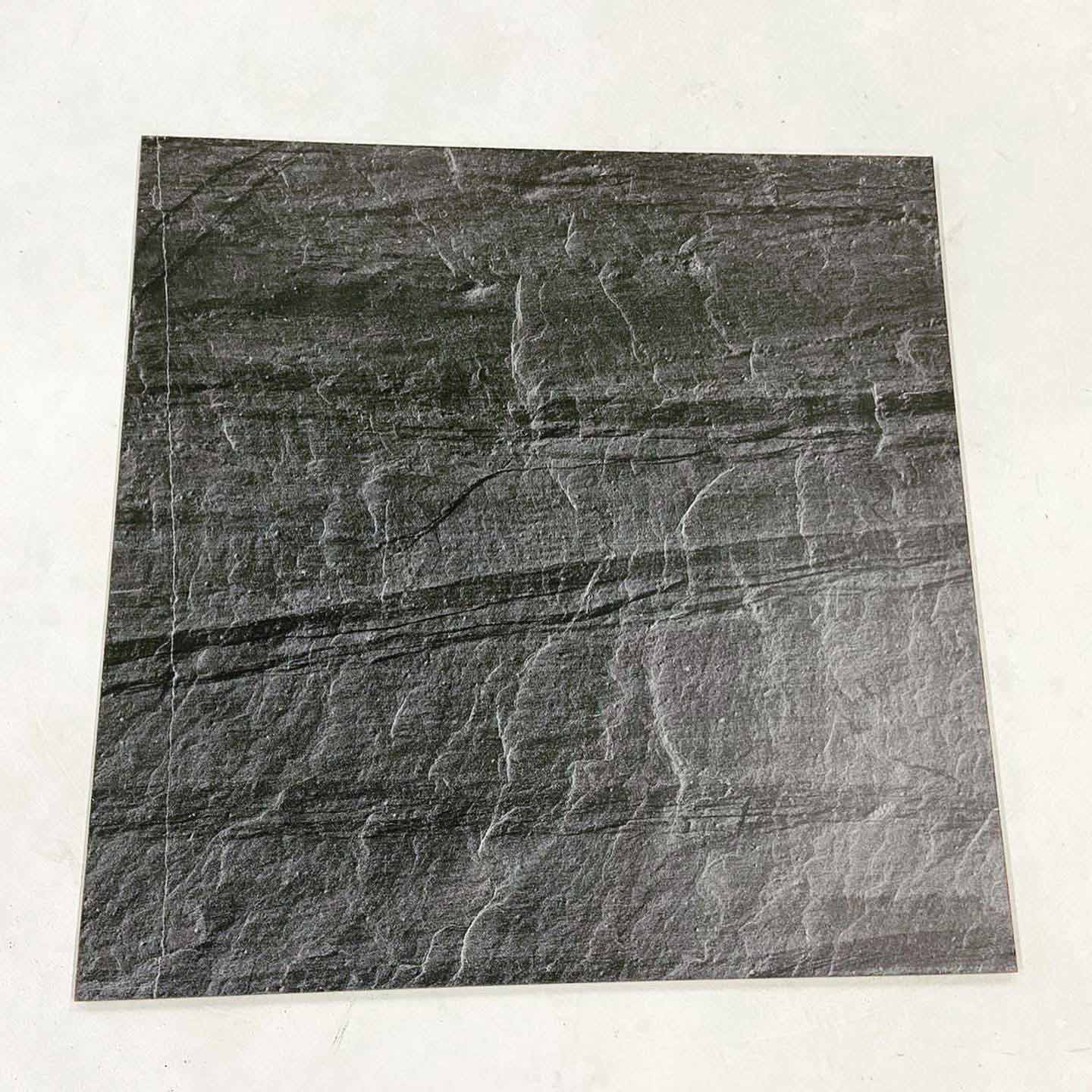

What trends are on the horizon in terms of materials, colours, and finishes? What will the materials of the future be?

We are moving towards sustainability and more locally sourced products. There are also circular materials, biodegradable materials, and a material that allows for safe close contact and interaction. The company that ends up creating masks with better ventilation or gloves that allow us to feel the warmth of the other person when you shake hands with them will be a great success.

Ver esta publicación en Instagram

I’ve also noticed the rise of virtual 3D technology, because virtual experiences in retail are very interesting. So, the material of the future should be sustainable, biodegradable, and virtual, even though that might sound a little strange.

Future projects

What’s your next project?

There are a lot of them. Firstly, promoting MIH. I would like to work on education in Galicia so that businesses start to choose new materials, new options, because so much is possible. We just have to ask the right questions and then evaluate which path we should take. I would like to communicate with and assist companies so that they aren’t so scared. Innovation is possible. Creation is possible. That’s what we are trying to do with Material Innovation Hub.

I’m also working trying out a new material in Galicia, in collaboration with a Galician university and a French manufacturer. If the prototypes turn out, it’s going to make a real splash in the luxury market.

I’m focusing on education and creating new projects, on getting the word out about Ydemaker and the MIH with interesting projects and by creating new materials that have different applications.

You mentioned the literature earlier. What exactly would you recommend to other professionals?

It’s going to sound a bit strange to the designers out there [but] I recommend reading scientific articles, something to do with science or physics, because knowing what you’re working with is one of the most important things. It’s like having a Swiss army knife. If you don’t know what knives you have available to you and how they work, you’re only going to use 20% of them. To get the most out of something, you have to go further and make sure you’re informed. And it’s not just about scientific articles. There’s also the general media. At any time, you might read something that makes you think. One thing I’ve learned is that, in this field, you must keep an open mind.

Is there somebody that really inspires you, someone that you really connect with?

Apart from the famous creator of Nokia, who had huge success with the idea of making phone covers using injection moulding, allowing us to change the phone’s colour, I wouldn’t really know how to choose a person that inspires me.

There are a lot of designers that attract my attention, like Dieter Rams or James Dysons, because they were innovative and thought about things in a different way. These designers took things that already existed and turned them on their head, which is what I like. I like thinking about how I can change something that already exists.