If we want to implement technological improvements that make our day-to-day lives in the city easier, why not transform industrial processes at the root? Here, we analyse the keys to the so-called Industry 4.0.

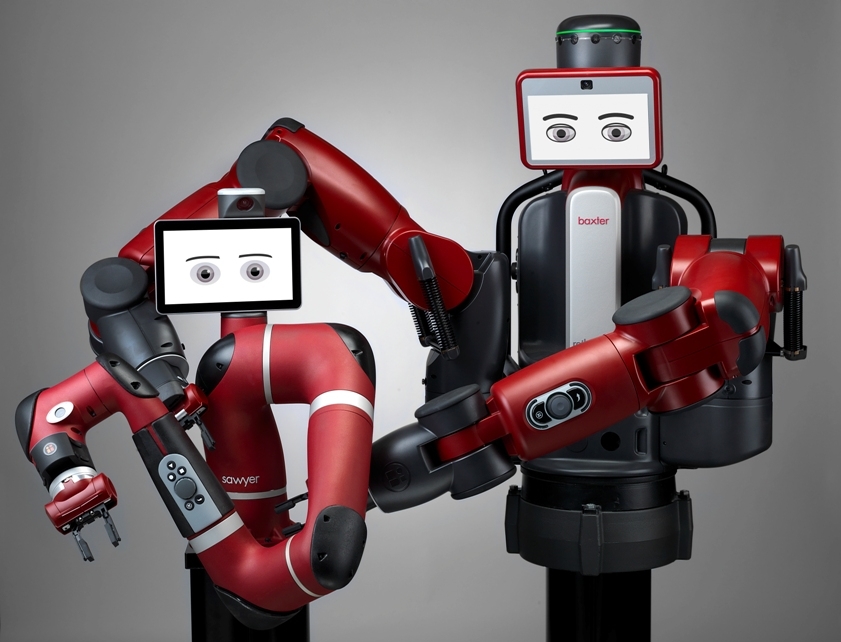

Flexible, multi-stage manufacturing, machine learning, advanced robotics…From using steam engines (1.0) to the current era, technology has been the compass showing the direction for new productions and services offered by the industrial sector. Socioeconomical development in recent history has been consolidated by the evolution of these advances: electrical energy (2.0) and the emergence of computing (3.0). The maturation of the latter brings with it a revolutionary method of production: the digital transformation (4.0).

Currently, those that are newly-qualified can establish their start-up without having to make a big financial investment, and in turn, they can be a partner for big industry. This change is being led by young companies that have been operating for less than ten years, and the technology that stands out the most is actually a mix of all of them – from analytics to robotics.

Which sectors are really being noticed in Industry 4.0? The automotive sector is one of them due to their use of robotics. To some extent, the maritime industry is another, thanks to the use of 3D printing for prototypes, as well as the telecommunication sector, which makes use of chatbots and advanced software. The banking sector is also an example of large-scale use of machine learning, big data, and analytics.

It’s not only machines that are becoming more intelligent, but also hyperconnected people that use their knowledge in a profound way thanks to data interpretation. Imagine finding out, in real time, the demand for a certain product or service, or being able to monitor processes or traceability. Thanks to big data, as well as other lesser-known tools, industries can meet the challenge of offering more personalised and sustainable products.

What would technology become if it wasn’t useful or wasn’t part of a social process? Above all, this industrial revolution, which rests on technology, is focused on people, from both a professional point of view, with those that have specific qualifications, and client demand. The executive Bernard Charlès explains the opportunity in this way in Retina: “Those that will change the rules in the futureare not those who have the most automated system of production, but rather those who have more experience and knowledge, who work in business environments and who integrate subcontractors as fully-fledged partners in the creation of value”.

Four concepts of Industry 4.0

It’s not only technological advances that are involved in Industry 4.0. Here, we highlight four keys to the revolution that go far beyond zeroes and ones.

- Educating people: machines won’t take over jobs, but rather will facilitate routine tasks. This level of specialisation requires a higher level of qualification, which businesses and institutions must work together on. People will develop their professional careers in a place where they can bring added value.

- Organisational transformation: the idea of departments which are separate from each other within a company is over. Data and processes are cross-sectional and affect all areas in a horizontal way, which facilitates less hierarchical environments to which the whole team contributes.

- Decentralisation of work networks: just like in the case of Facebook and its beginnings in a garage, it is no longer necessary to have a lot of machinery. A 3D printer can produce almost any component!

- Sustainability: in this technological revolution, more production capacity does not mean more pollution, but rather the opposite. Being able to control every part of the process makes it easier to conserve raw materials or energy, making for an industry that is not only sustainable, but also efficient and fast. A win-win for industry and society.